YOUR BENEFITS AT A GLANCE

increasing productivity

tool change < 0.5 s

tool change < 0.5 s Tool weight up to 85 kg possible

Tool weight up to 85 kg possible reduces downtime

reduces downtime high tipping moments

high tipping moments simple and fast integration and exchange

simple and fast integration and exchange

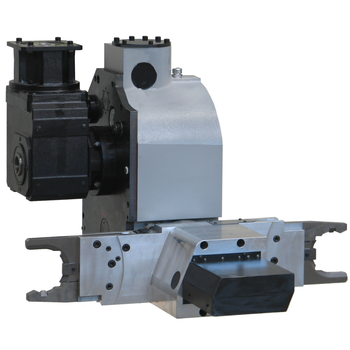

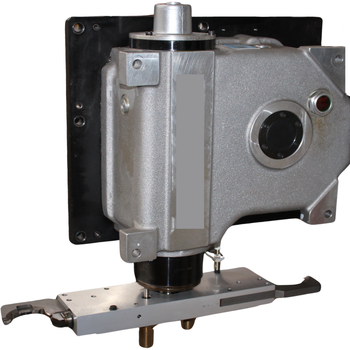

Unique flexibility

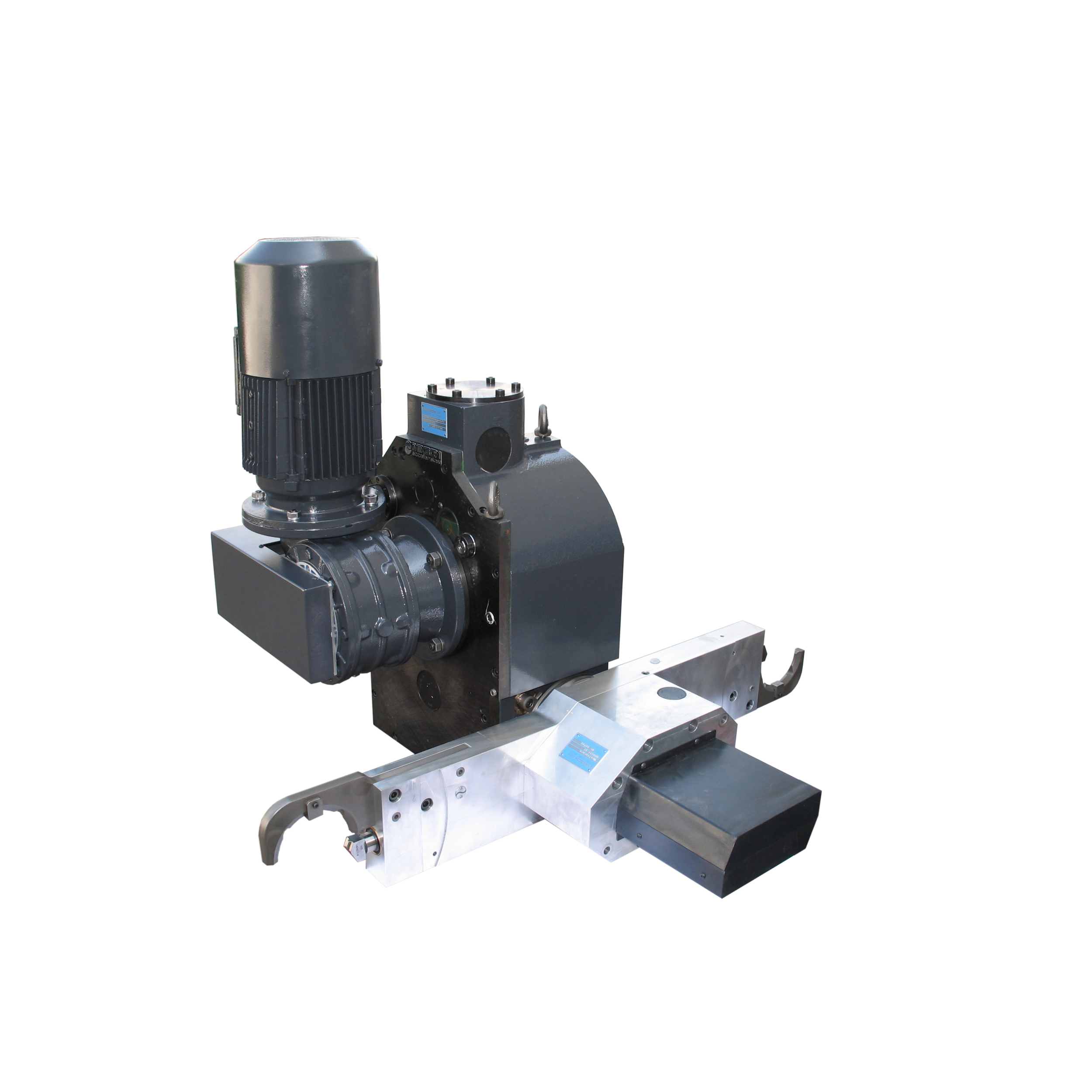

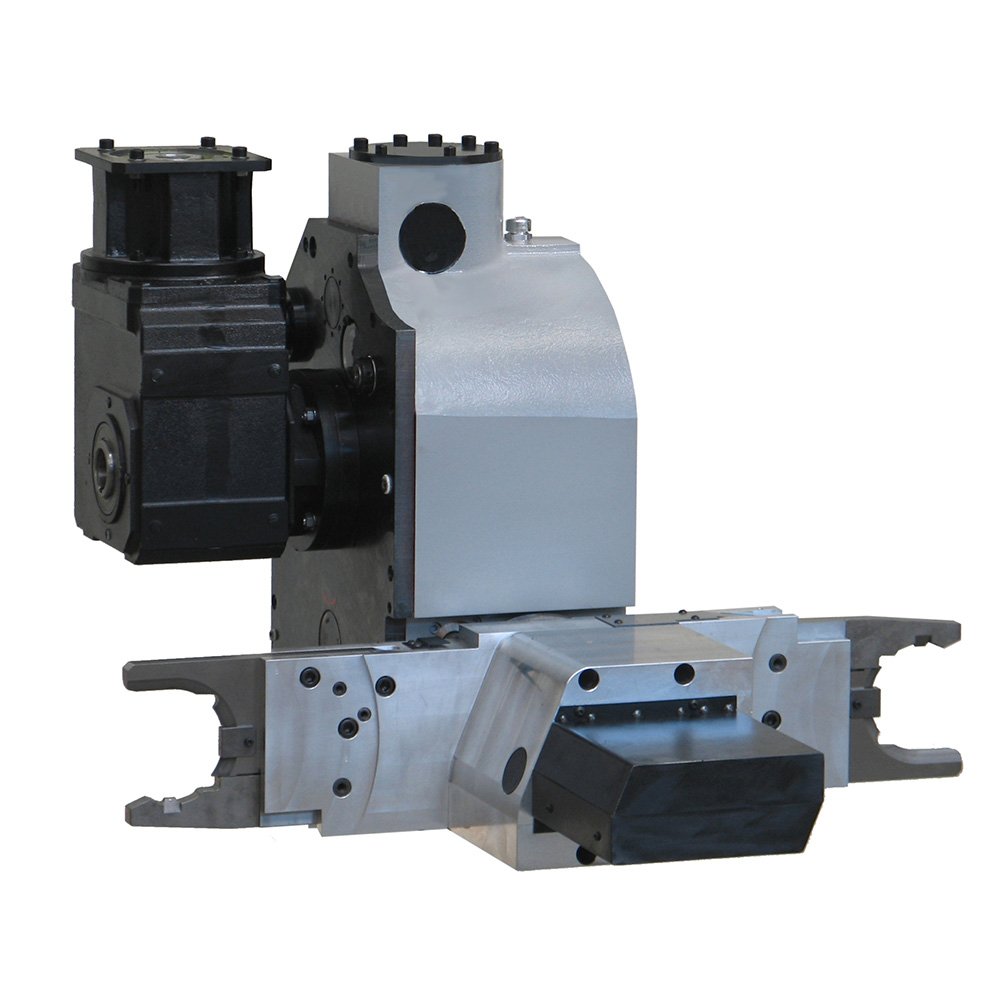

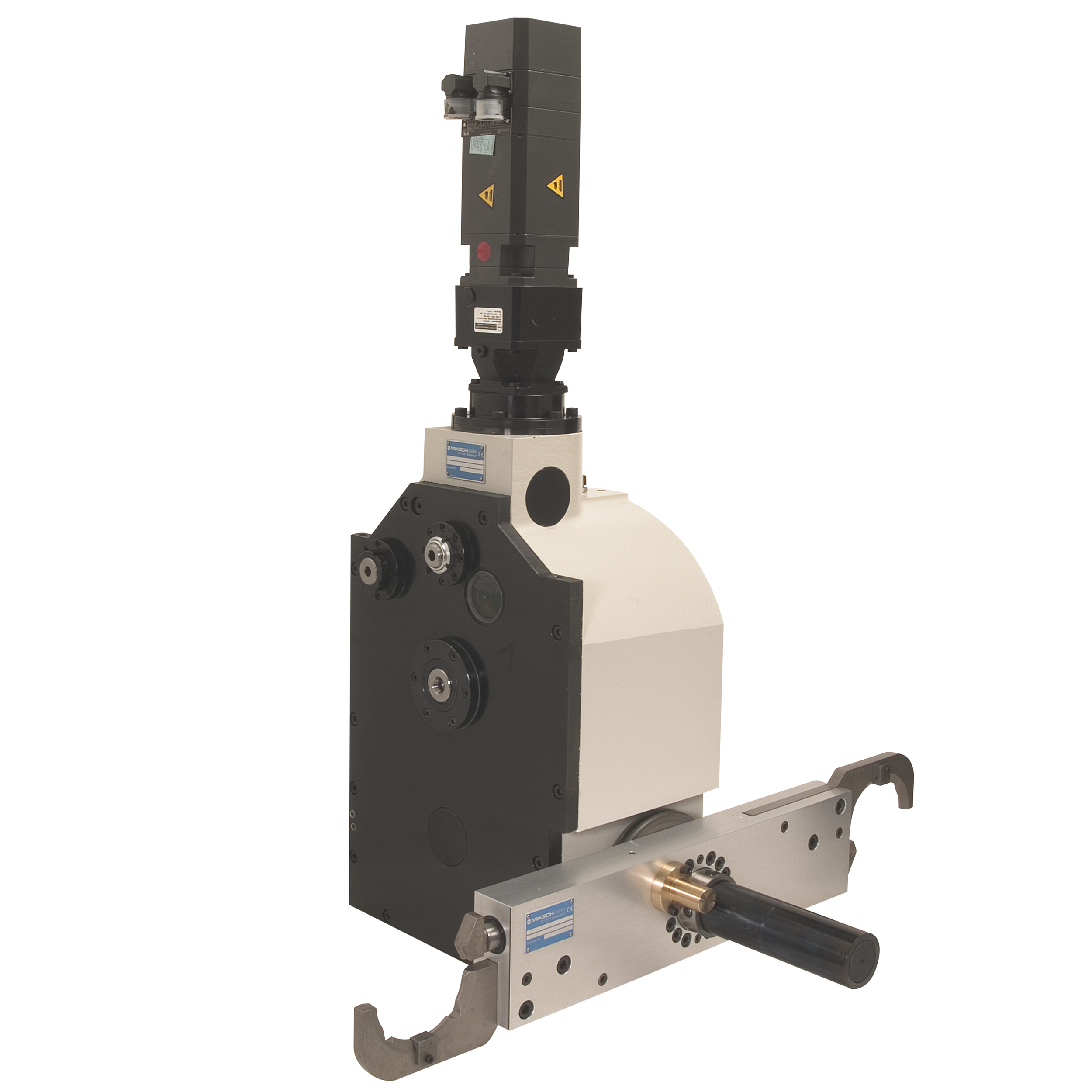

horizontal and vertical installation position

horizontal and vertical installation position Positioning next to or opposite the spindle

Positioning next to or opposite the spindle all common tool holders

all common tool holders Special recordings on request

Special recordings on request with or without pre-locking

with or without pre-locking

reducing costs

robust and reliable

robust and reliable long availability of spare parts

long availability of spare parts low maintenance

low maintenance no additional control required

no additional control required free of hydraulics

free of hydraulics

TECHNICAL DATA

| Designation | ATC, HTC, MTC |

| Tool weight | up to 85 kg |

| Installation position | horizontal and vertical |

| Positioning of the spindle | next to or opposite |

| drive | Three-phase brake motor, three-phase motor, servo motor |

| tool holders | all common tool holders Special recordings on request |

| Changeover time | < 0.5 s |